Benefit from fast, simple “tools free” design

Adjust your seasoning delivery with precision using our simple Uni-Spense worm gear control. Our ingredient distributors were developed for the food industry and are easy to changeover and clean.

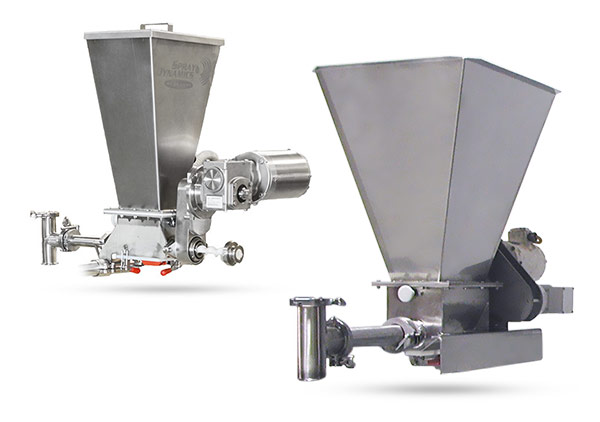

Spray Dynamics' Uni-Spense accurately dispenses or distributes dry coatings to a tumble drum, blender, scarf feeder, or conveyor belt.

Minimize bridging and voids, designed to reliably transfer powders, granules, chopped, shredded, and natural seasonings that have no flow agents. Available in lower-capacity SureFlow 100 or higher-capacity Uni-Spense III models.

IDEAL APPLICATIONS:

Benefit from fast, simple “tools free” design

Adjust your seasoning delivery with precision using our simple Uni-Spense worm gear control. Our ingredient distributors were developed for the food industry and are easy to changeover and clean.

We design equipment specifically for bakery food products, such as bagels, donuts, breakfast pastries, fruit-filled pies, cookies, crackers, and pretzels.

Meet demand while ensuring high quality, reducing labor costs, and improving yields with reliable automated systems for cannabis products such as gummies, edibles, dried flower, and crumble.

We supply coating, packaging, and inspection systems that can process all candy applications, from hard candies, toffees, gummy candies, and licorices, to chocolate bonbons and truffles.

We provide reliable and efficient product handling, weighing, and inspection systems for breakfast cereals and other nutritional grains, from flakes to granola and oats.

Our equipment processes sliced, diced, and shredded cheese solutions and includes conveying, weighing, and inspection equipment.

Our equipment systems feature fast, accurate, and reliable solutions for coffee and tea applications from Arabica, Italian roast, and beans blends to black, green, and herbal teas.

We are the leading solution provider and make the highest quality extruded or sheeted corn chips and offer complete line expertise, from raw corn to packaging.

We transform the raw recipe into the extruded, pulse, and legume snacks consumers know and love. We provide solutions to create cheese balls, cheese puffs, namkeen, and green peas.

As a key innovator in the snack industry, our fabricated chip frying systems are the industry’s first choice for this unique stackable snack food.

Our french fry and formed potato product systems are the workhorses of the industry. We process a broad range of styles, including straight cut fries, crinkle cut fries, curly fries, potato wedges, and variety of potato co-products. Working with our strategic partners, we are capable of full turnkey solutions, from potato receiving through palletizing.

Our dried fruit snack systems deliver the highest quality apple chips, as well as dried, blended, salted, and flavored fruit snacks.

Producing the world’s best tasting potato chips, our industry leading end-to-end systems process and package the highest quality potato chip products.

Our industry leading end-to-end systems process, inspect, and package the highest quality batch kettle-style / hard-bite chips.

Our high-performance continuous kettle-style / hard-bite potato chip processing and packaging solution produces the world’s most popular kettle-chips.

Our value-added systems prepare and cook consistently superior beef, pork, chicken, turkey, fish and other meat products including alternative meat to create a distinctive quality that stands out in the marketplace.

We process and package all types of nuts, including roasted, seasoned, coated, and glazed, with our turnkey systems.

Our pellet snack solutions deliver uniform processing of pork rinds, sea and rice pellets, other grain-based pellets, and collet snacks.

Our equipment improves line efficiency and boosts productivity, cuts waste, and enhances quality for dried or fresh formed pet food products and treats.

Our high-speed systems produce thousands of pounds per hour of quality plantain and banana snack products.

Our systems consistently produce value-added prepared foods, including onion rings, pizza rolls, taquitos, chicken pot pies, pot stickers, egg rolls, ready meals, and alternative meat products.

You can rely on our complete systems to prepare baked and fried tortilla products from corn and grain-based flours. From corn and masa preparation to inspection of packaged product, we can provide everything you need, including special continuous fryers for tostada and taco shell production.

Start with dry corn and manage every step of the way including the cook, simmer, and soak process followed by our complete solution, start-to-finish, to make all shapes of tortilla chips.

Simplify masa production by starting with corn flour and a masa flour mixing system, followed by sheeting and beyond to create all shapes of tortilla chips.

The Corn Masa Maker System (CMMS), Masa Maker, is our revolutionary way to make fresh masa faster. Produce high quality masa in minutes rather than hours compared to traditional systems.

We create fresh produce, fruit, vegetable and salad solutions, including weighing, packaging, and inspection systems.

Select a department to email: